Other systems help you track an inventory. MISys is designed to help you control your inventory.

Like other inventory systems, MISys can tell you what you have in stock and where its located. For MISys Manufacturing customers, that's simply not enough. Our customers enjoy a typical savings of 25-50% in inventory carrying costs because MISys has the ability to:

- Forecast inventory based on history, lead times, vendor performance

- Maintain accurate minimum order levels for "just in case" scenarios

- Let the system order only what you need, when you need it

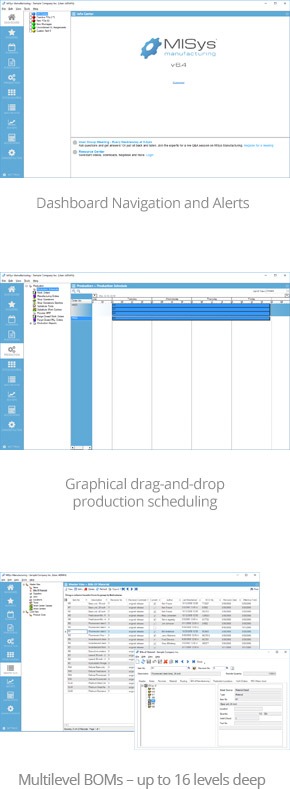

Every manufacturer needs the functionality included in the Basic Manufacturing module of MISys Manufacturing. Inventory control of raw materials and WIP, multi-level bills of material, BOM revision control, physical inventory cycle counting, and production work order processing. Start with one user license and expand with up to 256 concurrent users.

WHAT'S IN BASIC MANUFACTURING

- Manufacturing Inventory – Raw Materials and WIP

- Item Master Files

- Supplier Information

- Bills of Material, 16 levels deep.

- Multiple Warehouse Locations

- Work Orders

- Production Schedule

FUNCTIONALITY

- Use MISys to track raw materials and Work In Process (WIP).

- Create, maintain and revise multi-level Bills of Material (BOM) with full explosion to 16 levels.

- Maintain physical inventory on a net-change basis using cycle counting, eliminating the agony of annual inventory counts.

- Utilize standard, average, LIFO or FIFO costing methods that match your accounting practices.

- Generate Work Orders to document and track production activity.

- Create personalized alerts to warn of critical events and status in your operation.

- Track inventory in multiple warehouse locations. Move inventory from one location to any other.

- Maintain inventory levels with minimum, maximum and reorder points.

- Instantly display transaction history, where items are used (BOM Implosion) and outstanding order status.

- Access over 150 standard reports, or create your own reports using an industry-standard report writer – Crystal Reports.

- Establish and maintain "resources"used in production such as labor, electricity, consumable supplies, water.

- Utilize full "backflushing" to manage assembly inventories, automatically adjusting the inventory of component parts.

- Easily change the schedule of the production floor using a drag and drop graphical Gantt chart.

- Roll up cost adjustments to items through all BOM levels.

- Use the Multi-Currency capabilities to specify your home currency and the specific currency for any supplier.

- Identify physical inventory variances and valuation variances.

- Embed detailed item notes or attach a document and picture to any item record.

- Transfer manufacturing sub-ledger entries to GL at fiscal period end.

- Perform "what-if" inventory checks based on proposed transfer orders, and convert to purchase and/or production orders.

- Add an unlimited number of custom fields to the master files.